OSHA Reporting Season, Made Strategic

Turn OSHA 300A season into a leadership moment, not a paperwork scramble.

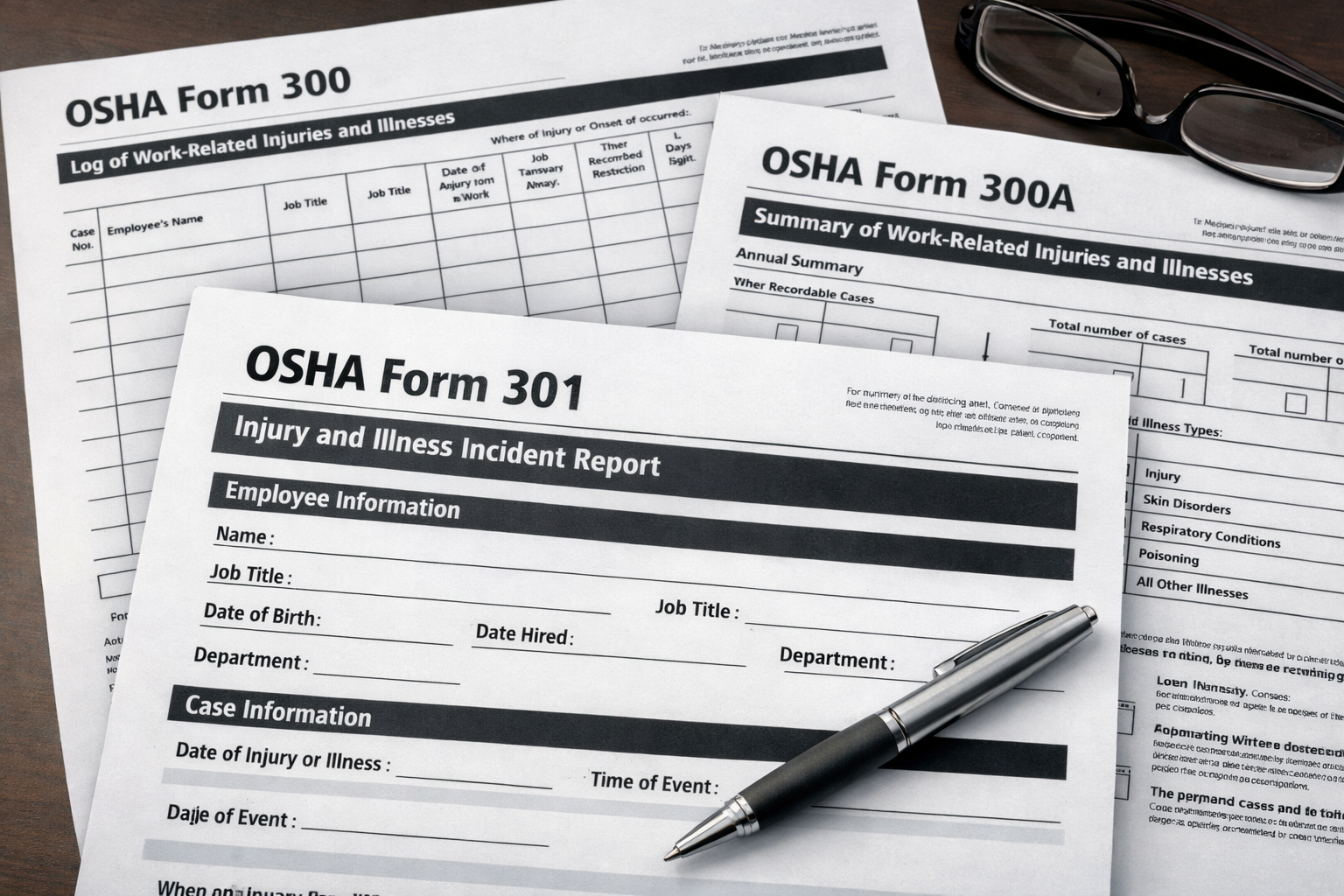

Every year, the same thing happens: late January hits, and safety teams switch into “recordkeeping mode.” You are chasing incident details, verifying classifications, checking locations, and making sure your OSHA 300 Log, 300A Summary, and 301 reports are accurate and defensible.

That work matters. But it can do more than keep you compliant.

When you treat OSHA reporting as a once-a-year checkpoint for leadership, it becomes one of the best opportunities you have to show business impact, earn trust, and secure support for what actually reduces risk.

This is the playbook.

The compliance trap

Most teams fall into a predictable pattern:

Track incidents in scattered tools (email, spreadsheets, paper, shared drives)

Reconcile records late, under time pressure

Post the 300A and move on

Repeat next year

OSHA 300A posting is required for covered employers, and the posting window runs February 1 through April 30.

When your program only shows up as a compliance event, leadership tends to see safety as a cost center. Your work becomes “admin,” not strategy.

Reframe OSHA reporting as a leadership checkpoint

The deadline creates something most departments do not get: a legitimate, annual reason to brief leadership on organizational performance.

Use it.

Your goal is not to walk in and say, “We met the requirement.”

Your goal is to walk in and say, “Here’s what the data tells us about risk, exposure, and where to intervene next.”

If you want a proven structure for building momentum fast, use this as a companion: Unlocking Safer Workplaces: A 30-Day Plan to Slash Injuries and Comp Costs.

What leadership actually cares about

Executives usually do not lose sleep over whether the 300A is posted. They worry about:

Workers’ comp costs and claim severity

Operational downtime and labor disruption

Customer and auditor confidence

Liability exposure and repeat issues

So translate recordkeeping into business language:

Cost pressure: connect injury trends to claim severity risk and operational disruption

Exposure: show where high-energy hazards and repeat conditions live

Control performance: show whether critical controls are actually holding

Move from incident logging to risk intelligence

OSHA reporting is built on lagging outcomes. That is not wrong. It is just incomplete.

If you want fewer serious events, you need leading indicators that tell you if prevention is working before someone gets hurt. OSHA has solid guidance on leading indicators and how to use them.

Here are the questions that change how leadership sees you:

Which sites, departments, shifts, or supervisors drive most events?

What injury types are trending and why?

Where are near misses and hazards rising, and how fast are they closed?

Which corrective actions are aging and tied to higher-severity exposure?

Where is engagement strong, and where is it breaking down?

If you want to go deeper on serious injury and fatality prevention concepts, align your annual review with the NSC SIF Prevention Model.

And if you want the modONE framework for doing this in the real world: How to Identify Life-Altering Safety Risks Before an Incident Occurs.

Build an annual safety narrative leaders will remember

Numbers alone do not persuade. A story does.

Use this structure:

1) Start with the year’s intent

What were you trying to change? What did you prioritize?

2) Show the trends that matter

Keep it simple. Year-over-year comparisons. One page if possible.

3) Connect actions to outcomes

What did you implement, where, and what changed?

4) Make the ask

One or two specific investments tied to specific exposures.

If you want a way to quantify engagement and performance in a clean executive story, use modONE’s measurement angle: What’s in a Number? How modONE’s Insights and Culture Index Drive Real Safety Improvements.

The hidden problem: manual recordkeeping blocks strategy

Most teams cannot do “strategic safety” because the paperwork eats the week.

Common blockers:

Incomplete records and missing details

Siloed information across systems

Delayed visibility that prevents intervention

Limited ability to spot patterns across locations

What “strategic OSHA reporting” looks like in practice

High-performing teams typically have five things in place:

Centralized data for incidents, training, audits, and corrective actions

Real-time visibility across sites and shifts

Automated OSHA-ready outputs so the annual scramble disappears

Leading indicators to predict risk, not just record outcomes

Executive-ready reporting built for decisions, not regulators

For a broader view of how software supports compliance, see: How Safety Management Software Helps with OSHA Compliance.

A simple OSHA season action plan

Before February 1

Reconcile incidents and confirm recordability decisions

Draft a one-page executive summary with trends and key exposures

February 1 to April 30

Use the posting period as a reason to schedule your leadership review

By March 2 (for covered establishments submitting electronically)

Throughout the year

Track leading indicators monthly (or weekly for higher-risk operations)

Standardize reporting and follow-up workflows so your data stays defensible

If you need the official forms package, OSHA provides the full set (300, 300A, 301).

Where modONE fits

modONE is built for the part that breaks most safety programs: consistent execution in the field.

That means:

App-free frontline delivery via SMS, email, and QR

Verified participation and simple sign-offs

Repeatable workflows for incident reporting and follow-up

Clear visibility into engagement and where it is slipping

OSHA-ready records without the year-end scramble

If you want to strengthen the training and audit side of the program as you mature, pair this with: Turning Pro: How modONE’s Premium Features Level Up Safety Training and Compliance.

About the author

John Turner is Chief Commercial and Marketing Officer at modONE. He works with safety leaders, operators, and insurance partners to build practical safety programs that drive measurable engagement, reduce serious risk exposure, and improve defensibility across crews, shifts, and locations.

Disclaimer: This article is for informational purposes and does not constitute legal advice. Always confirm your obligations based on your establishment, industry classification, and applicable state plan rules.