Workplace Fatigue Prevention: The Hidden Cost of Exhaustion Behind Injuries, Claims, and Compliance Failures

Fatigue is not a personal failing — it’s an organizational risk factor we’ve ignored for far too long.

Workplace fatigue prevention is often treated as a “nice to have,” but in reality it’s a hard ROI lever. Fatigue quietly shapes how people perceive risks, follow procedures, and react to hazards. If you’re serious about reducing injuries, near misses, claims, and compliance failures, fatigue has to move from the background into the center of your safety strategy.

Part 1: Fatigue – The Invisible Epidemic in Workplace Safety

Most organizations treat fatigue as an individual issue: someone didn’t sleep enough, didn’t manage their time, or “just needs to push through.” But at scale, fatigue is not an individual problem — it’s a structural one. It emerges from schedule design, shift rotations, overtime policies, staffing levels, and production pressure. When you zoom out and look across an entire workforce, you see that fatigue operates like a hidden system: it’s always on, always compounding, and always influencing outcomes, whether leaders track it or not.

From a scientific standpoint, fatigue is a measurable state of diminished performance caused by insufficient rest, poor recovery, or excessive cognitive and physical load. It directly affects how quickly workers process information, how consistently they follow procedures, and how effectively they notice and respond to hazards. Unlike a cut or a broken guard, you can’t see fatigue in a photo — but it’s embedded in the story behind many incidents. That’s why any serious workplace fatigue prevention approach has to go beyond posters and toolbox talks and into the design of how work actually happens.

When we talk about workplace fatigue, most people think of someone yawning on shift or needing an extra cup of coffee to power through. But true workplace fatigue is far more severe — it’s a biological and cognitive state in which:

Reaction times slow to levels similar to mild intoxication

Memory becomes unreliable

Hazard detection drops

Emotional tolerance decreases

Decision-making becomes impaired

Risk tolerance increases

According to multiple occupational health studies, 17 hours without sleep impairs coordination and reaction time on par with a 0.05 BAC. After 24 hours, performance degrades to a relative 0.10 BAC — over the legal limit for driving in all 50 states.

Now consider a forklift operator on third shift.

Or a crane operator after a double shift.

Or a delivery worker on the 11th hour of a 4-day week.

The physiology is undeniable: fatigue isn’t passive. It actively degrades performance in ways that directly correlate with incident severity, from near misses to fatal injuries. And if fatigue is quietly shifting the odds against your workforce every day, then any safety strategy that does not explicitly address it is incomplete by design.

Part 2: Fatigue by the Numbers — The Real Risk Data

If you want to understand fatigue, don’t start with opinions — start with patterns. Look at your last 3–5 years of incidents, near misses, and claims: when do they cluster, which roles are overrepresented, and what time of day or week do they occur? In nearly every high-risk industry, the same curve appears: events spike when people are either ramping up (early in the day or week) or hanging on (late in the shift or at the end of long work cycles). Those spikes are often fatigue signatures.

The challenge is that fatigue is rarely written down as the “cause” in official reports. It hides inside phrases like “employee failed to notice,” “did not follow procedure,” or “judgment error.” Without a structured way to tag and analyze those patterns, fatigue remains invisible in the data — even though it is active in the real world. That’s why pairing human insight with better analytics is critical for any modern fatigue risk management program.

Even without clinical measurements, fatigue shows up everywhere once you know what to look for. Review 5–10 years of incident reports, and you’ll see patterns emerge:

Industrial studies have found that up to 60% of injuries occur when workers have been on shift longer than 9 hours

Most OSHA-recordable incidents spike at two key points:

Early shift (6–9 AM) — circadian trough and sleep debt

Late shift and end of week — high cumulative fatigue

Across multiple high-risk industries (construction, energy, logistics), a “fatigue cluster” of claims appears at the intersection of:

Night shift + heat exposure

Seasonal peaks (especially during summer)

Heavy equipment use in back half of shifts

🔎 modONE’s recent polling confirms this lived reality.

When we asked: “When does fatigue hit hardest?”

68% said: “All of the above”

Translation: Fatigue is not situational.

It is cultural, systemic, and under-addressed.

Once you acknowledge that, a more honest picture emerges: fatigue is not a once-in-a-while variable; it’s a constant background force. The question is no longer, “Do we have fatigue?” but rather, “Where is it hitting us hardest — and what are we doing about it?” That shift in thinking is at the heart of effective workplace fatigue prevention.

Part 3: Fatigue Is the Root Cause Behind…

If you mapped out your incidents on a whiteboard and tagged each one for “signs of fatigue,” you’d likely find that a large portion share common markers: poor decision-making, missed steps, inattention to basic hazards, repeated errors in familiar tasks. These are not random, isolated human failures. They are predictable manifestations of a fatigued workforce in a high-demand environment.

Fatigue doesn’t show up with a label, but it shows up in how work gets done (or doesn’t). When crews operate in a constant state of catch-up, with limited rest and nonstop demands, risk escalates even when nothing else in the environment changes. Tools, procedures, and policies may all be technically sound, but a tired worker is less able to use them effectively. That is exactly why workplace fatigue prevention is a direct lever on injuries, claims, and compliance — not a side conversation.

1. Injuries and Near Misses

A fatigued worker may skip PPE. Miss a step. Fumble tools. Forget where a hazard is located.

Near misses become injuries. Minor injuries become recordables. Recordables turn into claims.

What looks like carelessness or inattention is often cognitive overload combined with insufficient recovery. Workers know the right thing to do — they’re just operating with diminished capacity to consistently execute, especially under pressure or distraction. Fatigue risk management starts by naming this openly and designing systems that assume humans will get tired and need support.

2. OSHA & Compliance Failures

Compliance is often framed as a knowledge issue: “Do people know the rules?” But in a fatigued environment, compliance becomes a stamina issue: “Can people keep following the rules, even when tired, rushed, or stressed?”

Fatigue doesn't just affect muscles; it affects memory and compliance discipline.

Forgetting to lockout/tagout

Misreading hazardous material labeling

Missing required documentation

These are not isolated “bad behaviors” — they are fatigue artifacts.

Each one also creates a paper trail that regulators and insurers see, often without the context that fatigue was driving the behavior. That disconnect can lead to the wrong corrective actions: more training, more rules, more forms — instead of addressing the underlying fatigue environment with smarter scheduling, better communication, and real-time support.

3. Claims & Insurance Costs

Carriers and brokers see patterns that employers sometimes miss: namely, that environments with unmanaged fatigue produce more — and more severe — claims. Fatigue amplifies the consequences of every other hazard in the system: poor housekeeping, equipment issues, production pressure, environmental extremes.

Ask any loss control specialist or TPA case manager — claims spike in environments with:

High shift turnover

Inconsistent break routines

High overtime cycles

Next year’s premiums are written in this year’s fatigue patterns.

Fail to manage fatigue, and you are essentially agreeing to higher future cost of risk. Manage fatigue intelligently, and you’re not just protecting workers — you’re protecting your balance sheet and improving your loss history for brokers and carriers.

4. Near Miss Blind Spots

A healthy safety culture depends on visibility: the more near misses you see, the more chances you have to intervene before something serious happens. Fatigue erodes that visibility on two fronts.

Fatigued workers report fewer issues.

Supervisors miss near misses entirely.

Safety leaders lose visibility into leading indicators.

Every unreported near miss today becomes a delayed loss tomorrow.

When people are exhausted, they are less likely to take the extra step of documenting an almost-event — especially if reporting is cumbersome or if they feel no one will act on it. That’s where a system like modONE can make the process quick, low-friction, and engaging — so even fatigued workers can still participate in keeping the system honest.

Part 4: Why Most Safety Programs Fail Fatigue

Most safety programs were built for a world where the biggest risks were physical: machine guards, fall protection, lockout/tagout. Those hazards are still real, but the underlying human factors — like fatigue — have become proportionally more important as production environments get faster, leaner, and more technology-driven. Unfortunately, many safety programs haven’t evolved at the same pace.

When fatigue is addressed, it’s often in the form of posters, one-off campaigns, or a single annual training. None of those are bad — but none of them are sufficient. They raise awareness, but they don’t change the daily workload, recovery patterns, or decision environments in which fatigue actually does its damage. Workplace fatigue prevention gets reduced to slogans instead of being integrated into operations.

Many companies continue to address fatigue through:

One-off training

Quarterly toolbox talks

Annual compliance training

Posters that say “Fatigue causes accidents”

But no one’s fatigue went away because of a poster.

The gap isn’t awareness. Workers know when they’re exhausted.

The gap is intervention. And systems.

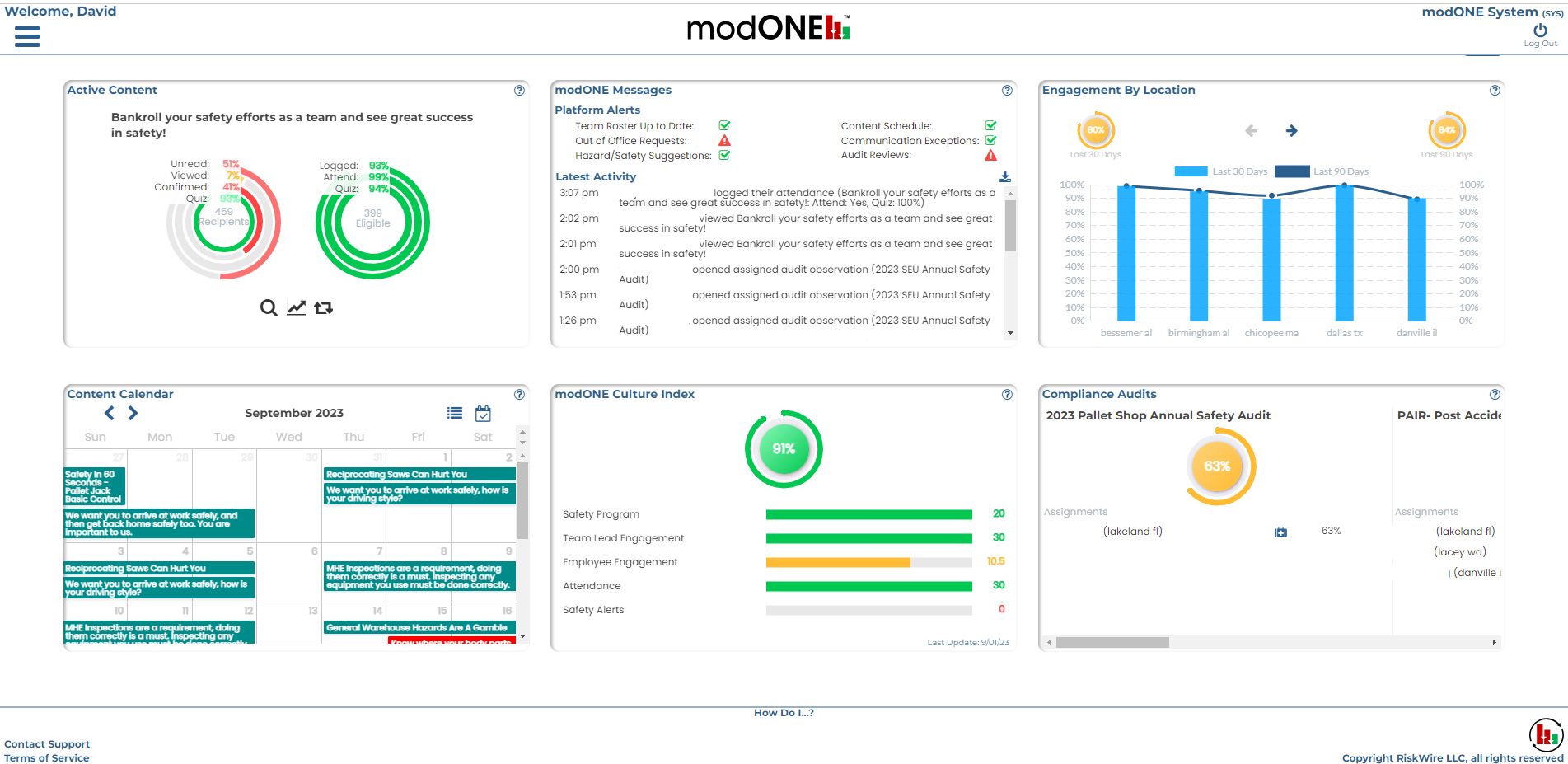

That’s the problem modONE set out to solve.

To truly manage fatigue, organizations need three things: a way to detect it, a way to communicate about it in real time, and a way to build habits that make the system more resilient. That requires data, delivery, and design — not just messages. That’s where AI, micro-learning, and behavioral nudges become a practical toolkit rather than buzzwords.

Part 5: How modONE Uses AI and Behavior Design to Break Fatigue Patterns

We’re not just automating safety. We’re systemizing resilience.

Where traditional safety tools often stop at documentation or one-way communication, modONE is designed to operate like a living system: listening, learning, and responding. The goal isn’t to replace human judgment — it’s to support it, especially when fatigue is quietly working against it.

modONE’s approach is grounded in 3 leverage points:

1️⃣ LLM-Powered Fatigue Risk Detection

Most organizations already have the raw material needed to understand fatigue risk — it’s just scattered across PDFs, spreadsheets, handwritten logs, claims files, and incident systems. Without a way to unify and interpret that data, you’re essentially flying blind.

Our controlled, closed-system LLM changes that by acting as a “pattern engine” that works only on your curated content and data. It doesn’t scrape the web. It doesn’t hallucinate random answers. It reads your world and your reality.

Our controlled, closed-system LLM analyzes hundreds of data points and safety signals — without ever leaving your environment.

It processes:

Incident reports

Pre-shift check-in data

Claims history

Safety audit findings

Job role profiles

Seasonal factors

In return, modONE can identify conditions such as:

“Forklift operators on the night shift during summer months have a 3x higher near-miss rate following weeks with >10% overtime.”

That’s not a spreadsheet. It’s pattern recognition powered by AI across your own operational realities.

From there, the system doesn’t just present a static report; it feeds those insights into scheduling, content recommendations, and targeted SafetyBot™ campaigns. In other words, your data doesn’t just describe fatigue — it helps prevent it from becoming the next loss.

2️⃣ Skill Builder: Targeted Micro-Training for Fatigue-Exposed Roles

Traditional training assumes that the same content, at the same time, will work for everyone. Fatigue risk doesn’t work like that, and neither should your training. Some workers are exposed more because of the work they do (e.g., night shift operators, drivers, maintenance teams). Others are exposed because of seasonality, project phase, or overtime demands.

modONE’s Skill Builder is designed to close that gap by allowing you — or the system — to build and schedule concise, role-specific micro-sessions that meet workers where they are: on their phones, in the field, in under 3 minutes.

Once fatigue risk is identified, modONE automatically builds and sends tailored micro-learning:

A 2-minute micro-module on spotting fatigue symptoms — delivered to all night shift supervisors

A quick safety story texted to drivers and equipment operators before peak season

An AI-generated heat awareness reminder during a heatwave

There’s no admin burden. No classroom booking. No LMS logins.

Workers consume it in seconds, supervisors get the data, and safety leaders gain visibility.

Beyond knowledge, these micro-sessions help normalize talking about fatigue as a shared risk, not a personal weakness. They also allow organizations to respond quickly when data shows that a particular crew, site, or role is drifting into a high-risk fatigue window.

3️⃣ Behavioral Nudges: The Most Powerful (and Overlooked) Tool in Safety Engagement

Most people know, intellectually, what they should do to be safer. The friction is not in knowing — it’s in remembering, prioritizing, and following through in the real world. That gap is where behavioral science shines and where nudges become powerful.

modONE treats nudges as tiny “course corrections” delivered at the right time, to the right people, in the right format (usually SMS, WhatsApp, or similar app-free channels). Instead of relying on workers to remember everything they learned last year, the system prompts them at the moment it matters most.

Using data from prior workforce performance, SafetyBot™ automatically delivers:

Pre-shift fatigue checks

“How ready are you for today’s tasks?”In-shift reminders

“Short break recommended. Here's why.”Post-shift follow-ups

“Did you experience any unexpected strain today?”

These aren't bells and whistles. They’re cognitive reset points that drive safer behavior.

Over time, those nudges accumulate into new habits. Crews start to expect check-ins. Supervisors become more fluent in discussing fatigue. And leadership gains a continuous stream of engagement and risk data that is far richer than what a single annual survey could ever provide.

Part 6: Outcomes – What Happens When You Operationalize Fatigue Intelligence

When fatigue becomes a managed variable instead of an invisible one, the entire profile of risk and performance changes. You don’t just see fewer incidents — you see cleaner operations, more consistent performance, and a workforce that feels seen and supported.

The impact shows up in both hard numbers and softer, cultural shifts. Claims and recordables are leading indicators for carriers and regulators, but for workers, the change is more personal: they feel safer, more respected, and more in control of their day.

Companies using modONE report:

Reduced incident rates on fatigue-exposed tasks and shifts

Higher engagement among shift workers and frontline teams

Lower claim frequency over 6–12 months

Improved compliance discipline across multi-shift environments

Predictable risk visibility (instead of reactive reporting)

Risk goes from unknown to manageable.

As your fatigue intelligence matures, you can also begin to experiment: adjusting shift patterns, modifying start times, pairing high-risk tasks with more robust pre-shift checks, and using SafetyBot™ campaigns to support major operational changes. Instead of guessing what might work, you can see it — in engagement data, near-miss reporting, and incident trends.

Final Thought:

Visibility → Intelligence → Action

Fatigue is not a moral failing or a compliance box to check.

It’s a measurable, preventable safety risk.

The organizations that recognize it — and operationalize against it — will experience:

Fewer claims

Safer shifts

More resilient cultures

Lower cost of risk

Higher worker retention

This is what modONE is designed for.

Want to see how your own data can reveal hidden fatigue risks?

Schedule a walkthrough of modONE’s fatigue intelligence, Skill Builder, and SafetyBot™ nudges.

SEO FAQ Section

Q1: What is workplace fatigue prevention?

Workplace fatigue prevention is the practice of identifying, managing, and reducing the impact of physical and mental exhaustion on workers. It includes smarter scheduling, monitoring leading indicators, using tools like pre-shift check-ins, micro-learning, and behavioral nudges to reduce fatigue-related errors, injuries, and claims.

Q2: How does fatigue contribute to workplace injuries?

Fatigue slows reaction times, lowers hazard awareness, and impairs decision-making. This increases the likelihood of missed steps, PPE errors, misjudged movements, and delayed responses — all of which can turn ordinary tasks into injury events or serious near misses.

Q3: Can AI really help detect fatigue risk in the workplace?

Yes. AI can analyze patterns in incidents, claims, pre-shift surveys, overtime data, and job roles to surface where and when fatigue risk is highest. At modONE, a closed LLM helps identify those patterns and trigger targeted content, micro-training, and nudges for the crews and shifts most at risk.

Q4: What are examples of fatigue risk management controls?

Controls include better shift design, enforcing rest periods, rotating high-risk tasks, pre-shift readiness checks, micro-learning on fatigue awareness, and nudge-based reminders to rest or refocus. Digital tools like modONE make these controls scalable and measurable.

Q5: How can safety leaders start improving fatigue management today?

Start by reviewing when and where incidents occur, talk to supervisors about perceived fatigue hotspots, and implement simple pre-shift check-ins for high-risk roles. Then, layer in platforms like modONE to automate micro-training, nudges, and analytics so workplace fatigue prevention becomes part of daily operations — not a one-time campaign.